Production Scheduling with Optimal Utilization of Skill Matrix

Lean manufacturing methodology encourages training of workers for multiple skills in order to increase the flexibility of worker assignment, improve flow, lead times and throughput. According to Jun Nakamuro,

Taiichi Ohno’s focus shifted to providing the workforce with flexibility and ownership to better match cycle time to customer demands, particularly in high mix/low volume production line.

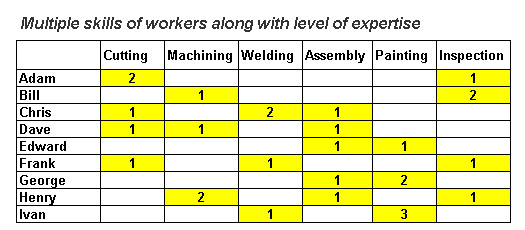

Usage of multi-skilled workers reduces the occurrence of events  in which a worker of a specific skill sits idle when a lot of work waits for a worker of another skill. A skill matrix nicely shows the association between workers and skills. With skill matrix, a supervisor has a better chance of assigning, at any given time, a right worker to an operation and ensuring that the operation is not delayed due to unavailability of right worker. However, this advantage with skill-matrix is restricted to real-time decision making on shop floor.

in which a worker of a specific skill sits idle when a lot of work waits for a worker of another skill. A skill matrix nicely shows the association between workers and skills. With skill matrix, a supervisor has a better chance of assigning, at any given time, a right worker to an operation and ensuring that the operation is not delayed due to unavailability of right worker. However, this advantage with skill-matrix is restricted to real-time decision making on shop floor.

People without much expertise in production scheduling (over a time period like a week or more) take advantage of skill matrix only in real time. For a given skill matrix, they are unable to predict:

- How work orders are going to progress over time

- When work orders will be completed

- When a lot of work will wait for a skill.

They are also unable to predict the above when a major change occurs in skill matrix or when a skill set available in a shift changes.

Knowledge of skill matrix makes real-time worker-operation assignment simpler and easier and it also gives confidence that factory productivity will improve with multi-skilled workers. But, real-time worker-operation assignments are not enough for optimal utilization of skill matrix for maximizing factory productivity over time. Such optimization involves the best planning for assignment of workers of right skills to operations over time for getting maximum throughput. The difficulty with this optimization increases due to machine requirements and precedence relations of operations.

Knowledge of skill matrix makes real-time worker-operation assignment simpler and easier and it also gives confidence that factory productivity will improve with multi-skilled workers. But, real-time worker-operation assignments are not enough for optimal utilization of skill matrix for maximizing factory productivity over time. Such optimization involves the best planning for assignment of workers of right skills to operations over time for getting maximum throughput. The difficulty with this optimization increases due to machine requirements and precedence relations of operations.

Proposed Solution

Our software tools, Schedlyzer and Schedlyzer Lite are very efficient for optimally scheduling production/service systems which involve multi-skilled workers. They fully utilize the available skill-matrix in generating an optimal production schedule. Both tools predict workflow, formation of bottlenecks and order completion times in a realistic fashion. They also facilitate fast and extensive what-if analysis of schedules with respect to changes in worker-skill information and help with proactive planning for training workers on additional skills. Our software helps the organization maximize productivity from the existing set of skilled workers and find cost-effective opportunities for increasing the flexibility of workers.

Our software helps the organization achieve the objective:

Get the maximum productivity from the existing workforce and find cost-effective opportunities for increasing the flexibility of workers.

For free evaluation of the true practical merit of our software, we offer duly configured, fully functional, 60-day, trial copies of our scheduling software. Contact us for a free trial copy.