Schedlyzer – Scheduling Software for High-Mix, Low-Volume, Make-To-Order Production

Schedlyzer is a simple, powerful, versatile, appropriate software tool for production scheduling in high-mix, low-volume, make-to-order systems in a wide range of job shops. It is an ideal tool for a small or mid-sized job shop that looks for powerful scheduling software at an affordable price without bells and whistles.

Nature of Production in Job Shops

A vast majority of job shops can be described as production units of types high-mix, low-volume (HMLV), make-to-order (MTO), engineer-to-order (ETO), custom, etc. These shops keep receiving a stream of diverse customer orders at unpredictable times for unpredictable quantities and process and resource requirements. Most often, a job shop needs to make a product only after receiving an order for the product and it has to make the product within a stipulated lead time. Several jobs may simultaneously progress on shop floor competing for shared resources to meet respective due dates.

Difficulty with Production Control and Management in Job Shops

High-mix, low-volume, make-to-order job shops are usually small in size and revenue and use very limited resources which may even include multitasking machines and multi-skilled workers. The rapidly changing product mix creates shifting bottlenecks in production.  Marshaling limited resources optimally for making products against received orders by specified due dates in such environment is a challenge regularly faced by many job shops. Significant interruptions in resource availability and material delays further increase the complexity. Production scheduling in high-mix, low-volume manufacturing units of this type is quite difficult in general. Therefore, production control and management is also difficult in many job shops.

Marshaling limited resources optimally for making products against received orders by specified due dates in such environment is a challenge regularly faced by many job shops. Significant interruptions in resource availability and material delays further increase the complexity. Production scheduling in high-mix, low-volume manufacturing units of this type is quite difficult in general. Therefore, production control and management is also difficult in many job shops.

Various Methods for Production Control and Management in Job Shops

It is rational to simplify production system of a job shop as much as possible to reduce the difficulty with production control and management. Such simplification will enable job shops to manage production easily and efficiently. This is the approach adopted by lean manufacturing and theory of constraints (TOC) for any production system. However, many small and mid-sized job shops are unable to afford capacity enhancements as much as required for system simplification. Those shops still face a lot of difficulty to manage production after a partial system simplification. Some job shops implement pull methods which include kanban, CONWIP or POLCA of Quick Response Manufacturing (QRM).

A vast majority of job shops adopt production scheduling as a method that helps with production control and management. Many job shops generate production schedules using whiteboards, Excel, project management software, scheduling modules of ERP, advanced production scheduling (APS) software or finite capacity scheduling (FCS) software.

Schedlyzer – Powerful Software for Production Scheduling in High-Mix, Low-Volume Manufacturing

Many job shops are currently unhappy with scheduling by any tools other than the best-of-breed FCS / APS software which are based on powerful, scientific scheduling logic. For scheduling their high-mix, low-volume production, they are looking for such software along with interface for integrating the software with their ERP/MRP system. Our software Schedlyzer is a versatile, powerful and affordable tool for scheduling a wide range of high-mix-low- volume, make-to-order production units. It s based on a highly versatile paradigm of job shop production and powerful, scientific, finite capacity scheduling (FCS) logic. Unlike typical FCS software, Schedlyzer takes into account job information, resource information and also uncontrollable natural variation in production for generating meaningful schedules. Its high speed to generate a rational schedule facilitates fast, accurate and extensive what-if analysis of production.

A Few Merits of Schedlyzer

Schedlyzer is an ideal tool for production scheduling in high-mix, low-volume environment. It helps extract the best production performance from the existing finite set of resources first. Subsequently, it helps find and implement the most cost-effective changes to the system one by one for improving plant production performance. It identifies permanent and temporary bottlenecks in production and supports proactive capacity planning to mitigate the bottlenecks. In this fashion, it helps with lead time control, on-time delivery, order priority changes and acceptance of more orders including some rush orders. High-mix, low-volume production consists of two types of variation:

- Result of uncertain events and uncontrollable natural causes in the system including errors in estimated process times of operations, interruptions in resource availability and material delays

- Large, known variation in process requirements of diverse orders.

Schedlyzer efficiently handles both types of variation by taking into all relevant data and allowing job waiting times to some extent at bottlenecks (to absorb uncontrollable natural variation). Development of Schedlyzer is based on the premise that control and management of job shop production will be more efficient with the help of:

- Operations scheduling with maximum synchronization

- Reliable prediction of work flow, job completion times and bottleneck formations

- What-if analysis of production

- Proactive capacity planning

- Intelligent decision support to managers

- Capability of salespersons to quote rational lead times for new orders.

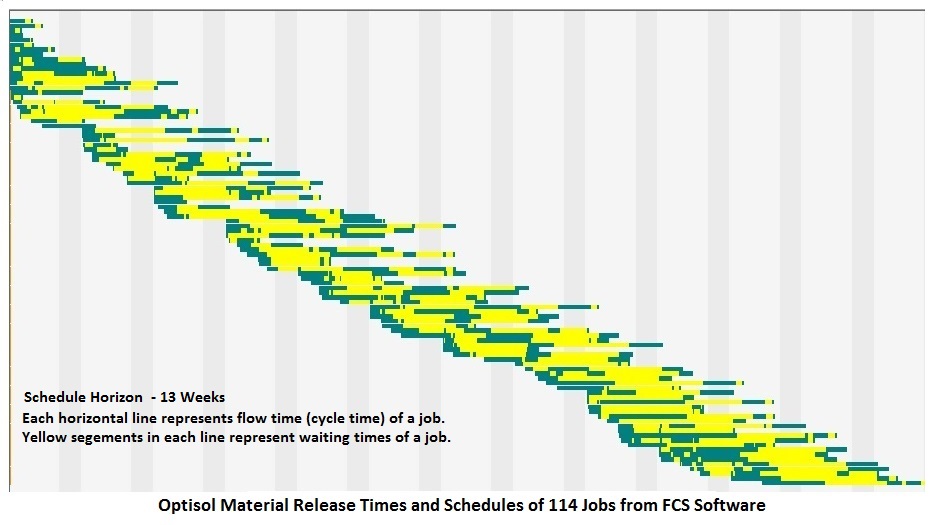

Schedlyzer supports the objectives of maximizing on-time delivery, throughput and overall resource productivity and minimizing WIP, production lead times and firefighting. As shown on our web page, Lean Job Shop Production, optimal job release times determined by Schedlyzer ensure minimal WIP and job lead times.

Some Important Functions and Features of Schedlyzer

Display of Current Status of Jobs

Schedlyzer shows all operations which are either ongoing or ready for processing at the time of scheduling. It also shows which of those operations are scheduled to start at that time. This information can also be seen for each work center separately.

Fixing Rational Lead Times for New Orders

For many job shops, the problem of managing order-driven, high-variety production starts with determination of lead times for new orders. This is due to the changing product mix and shifting bottlenecks. Schedlyzer finds a right lead time for each new order based on the existing workload and resource capabilities and capacities.

Determining Optimal Start Times for Jobs

One of the most difficult decisions to be made in high-mix, low-volume, make-to-order production is to find a right start time for each job based on the existing workload and resource capacities. Early job start times can result in higher WIP and longer lead times. On the other hand, late start may result in the reduction of shop productivity, resource utilization and on-time delivery. Schedlyzer finds right job start times (as shown on the page, Lean Production) as part of schedule balancing both risks. This is done by taking into account process and resource requirements of jobs, due dates and resource capacities.

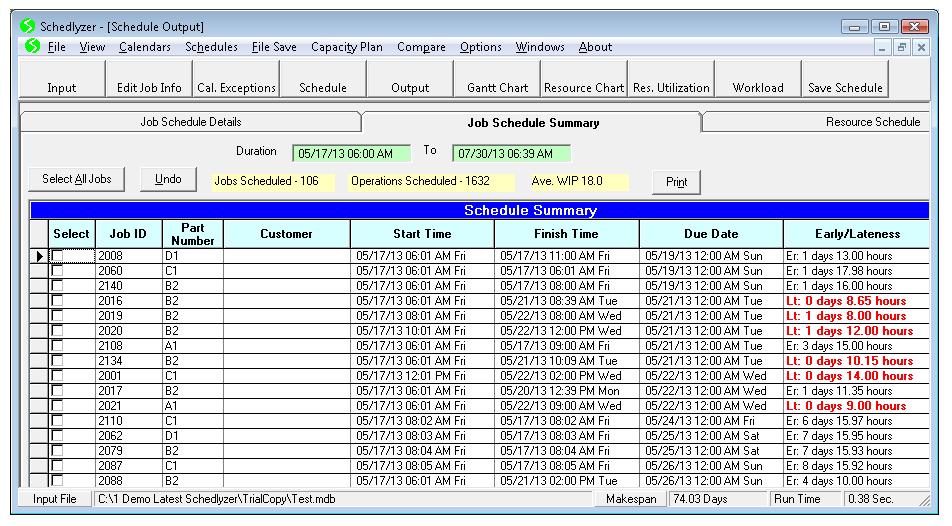

Generation of Job Schedules and Dispatch Lists for Resources

For day-to-day production control, supervisors and workers need a display of current status and projected progress of jobs and a dispatch list (operation sequence) for each resource. Schedlyzer generates both of them as part of the scheduling exercise. It reschedules workload and revises the output almost instantaneously whenever required.

Handling Vendor Operations and Material Available Times

It is not practically easy for a job shop to monitor the progress of vendor operations as done for internal operations. So, job shops usually face some difficulty to include vendor operations in the schedule. Material supply may sometimes be delayed unexpectedly. Schedlyzer efficiently incorporates vendor operations and material available times into production schedule.

Handling Multi-Resource Requirements of Operations and General Precedence Relations among Operations

An operation may require two or more resources like machine and worker simultaneously and wait until all the required resources are available. Unlike many scheduling software, Schedlyzer can easily schedule such multi-resource requirements of operations.

Schedlyzer also accepts general precedence relations among operations of any job. Therefore, it can easily schedule project-oriented production where each order can be viewed a project of several tasks.

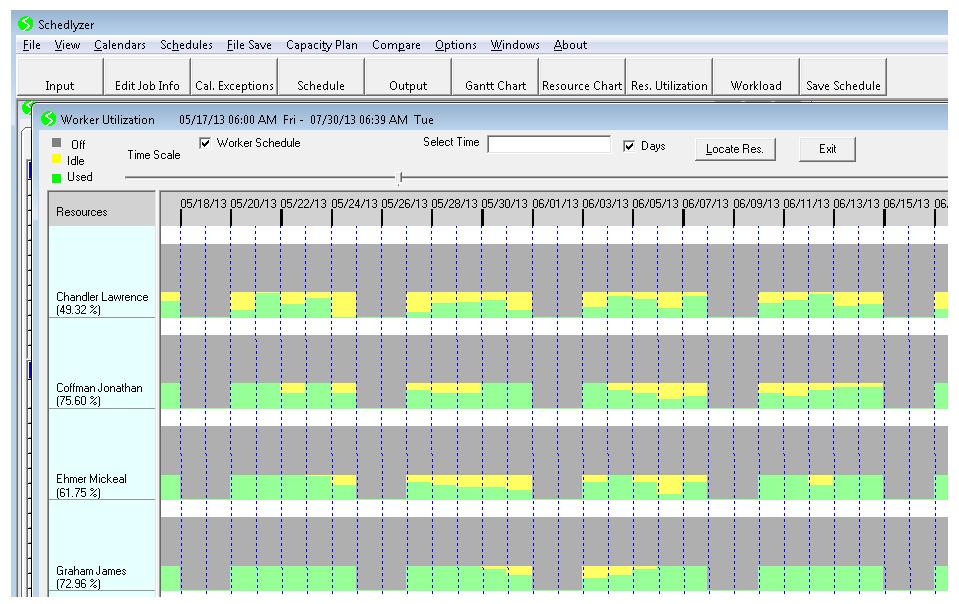

Optimal Utilization of Multi-Functional Machines and Multi-Skilled Workers

Small and mid-sized job shops need to perform a variety of operations as required by customer orders. They usually employ multi-skilled workers for achieving the maximum productivity of workers. Similarly, they may also use multi-functional machines for achieving the maximum productivity of machines. Resources may have different working hours (shifts / calendars) and calendar exceptions like machine breakdowns and worker absenteeism. Schedlyzer generates a high quality schedule by optimally assigning multi-skilled workers and multi-functional machines to operations. Such schedules improve shop throughput, on-time delivery, WIP and order lead times.

Prediction of Workflow, Bottlenecks and Job Completion Times

A reliable prediction of workflow, bottleneck formations and job completion times can give great confidence to people who manage high-variety production. Control and management by reliable workflow prediction is efficient for high-variety production. Schedlyzer offers such prediction in the form of schedule by taking into account both resource availability and natural variation in the system.

Determining Optimal Start Times for Jobs

One of the most difficult decisions to be made in high-mix, low-volume, make-to-order production is to find a right start time for each job based on the existing workload and resource capacities. Early job start times can result in higher WIP and longer lead times. On the other hand, late start may result in the reduction of shop productivity, resource utilization and on-time delivery. Schedlyzer finds right job start times (as shown on the page, Lean Production) as part of schedule balancing both risks. This is done by taking into account process and resource requirements of jobs, due dates and resource capacities.

Generation of Job Schedules and Dispatch Lists for Resources

For day-to-day production control, supervisors and workers need a display of current status and projected progress of jobs and a dispatch list (operation sequence) for each resource. Schedlyzer generates both of them as part of the scheduling exercise. It reschedules workload and revises the output almost instantaneously whenever required.

Handling Vendor Operations and Material Available Times

It is not practically easy for a job shop to monitor the progress of vendor operations as done for internal operations. So, job shops usually face some difficulty to include vendor operations in the schedule. Material supply may sometimes be delayed unexpectedly. Schedlyzer efficiently incorporates vendor operations and material available times into production schedule.

Handling Multi-Resource Requirements of Operations and General Precedence Relations among Operations

An operation may require two or more resources like machine and worker simultaneously and wait until all the required resources are available. Unlike many scheduling software, Schedlyzer can easily schedule such multi-resource requirements of operations.

Schedlyzer also accepts general precedence relations among operations of any job. Therefore, it can easily schedule project-oriented production where each order can be viewed a project of several tasks.

Optimal Utilization of Multi-Functional Machines and Multi-Skilled Workers

Small and mid-sized job shops need to perform a variety of operations as required by customer orders. They usually employ multi-skilled workers for achieving the maximum productivity of workers. Similarly, they may also use multi-functional machines for achieving the maximum productivity of machines. Resources may have different working hours (shifts / calendars) and calendar exceptions like machine breakdowns and worker absenteeism. Schedlyzer generates a high quality schedule by optimally assigning multi-skilled workers and multi-functional machines to operations. Such schedules improve shop throughput, on-time delivery, WIP and order lead times.

Prediction of Workflow, Bottlenecks and Job Completion Times

A reliable prediction of workflow, bottleneck formations and job completion times can give great confidence to people who manage high-variety production. Control and management by reliable workflow prediction is efficient for high-variety production. Schedlyzer offers such prediction in the form of schedule by taking into account both resource availability and natural variation in the system.

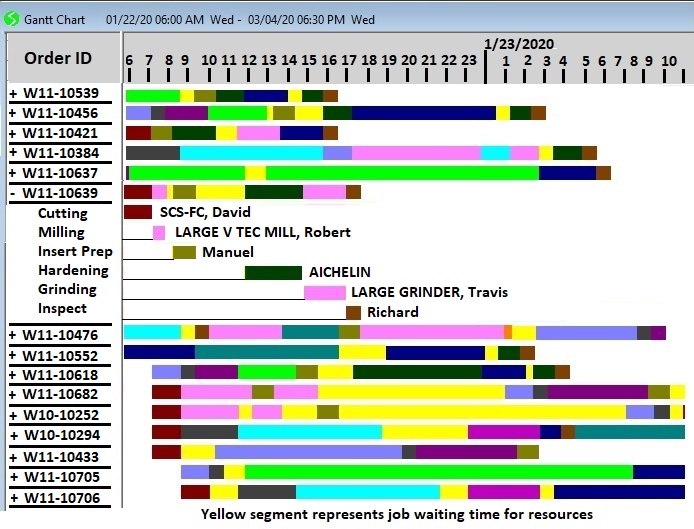

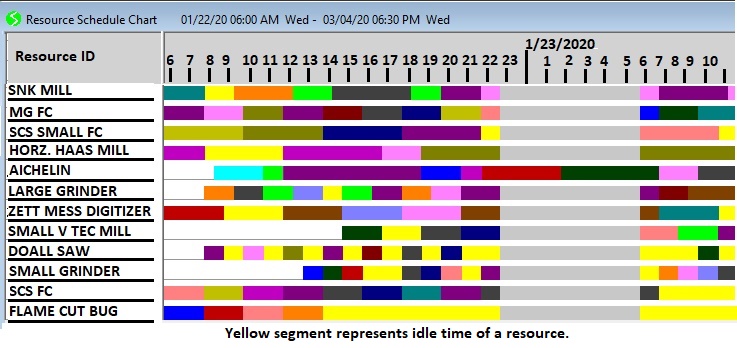

Schedule Output

Schedule output consists of job schedule summary, resource utilization percentages (for any selected time period), projected daily resource utilization levels, detailed job schedules and detailed resource schedules. Schedlyzer provides powerful graphic features and drag-and-drop options. Gantt charts graphically display, with zooming option, summarized job schedules and detailed schedules of jobs and resources. Drag-and-drop operation is available on Gantt chart to manually change a schedule generated by Schedlyzer without violating any constraints. Schedlyzer however reduces the need for drag-and-drop operations by scheduling all the workload efficiently and automatically with the help of advanced algorithms. Users can save schedule output in many formats including Excel.

Primary Benefits of Schedlyzer

- Higher on-time delivery

- Improved throughput

- Shorter lead times

- Low inventory

- Higher resource utilization

- Less firefighting

- Efficient bottleneck management

- Proactive capacity planning

- Easier handling of rush orders and order priority changes

- Quick, optimum response to changes in production

Although the powerful software, Schedlyzer does not require users to have rigorous training for several hours, the users need to have some help from us in the initial stage. This software can be used as standalone scheduling software or it can be integrated with any popular ERP package. Schedlyzer Lite is a lighter, low-cost version of Schedlyzer which is almost as powerful as Schedlyzer for a majority of job shops. To have a brief idea of how Schedlyzer Lite works, you may watch our 9-minute YouTube Video on Job Shop / Machine Shop Scheduling.

In spite of great promise from vendors, you should not trust any scheduling tool without evaluating it for your own system. Contact us for a free, duly configured, fully functional, 60-day trial copy of the software. Before giving the free trial copy, we would first present a live web demo of Schedlyzer and configure the trial copy as required for your system. We would also offer you free help during trial runs.

Free, fully functional, 60-day trial copies of Schedlyzer.

We offer free, fully functional, 60-day trial copies of our production scheduling software, Schedlyzer.